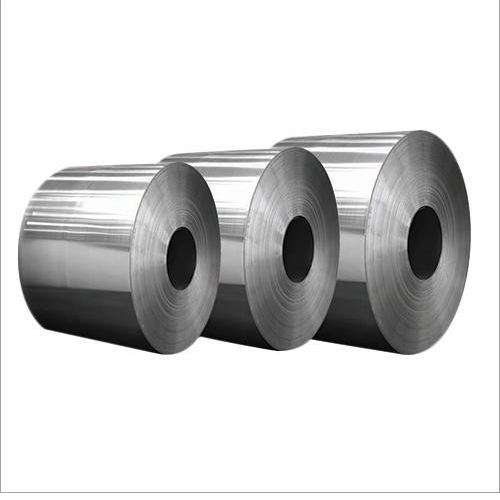

GI Coils Roll

Price 55 INR/ Kilograms

GI Coils Roll Specification

- Surface Treatment

- Galvanized

- Usage

- Automobile Industry, Sheet Metal Manufacturers, Pipes & Tubes, Industrial & Engineering Parts, White Good Manufactures, etc.

- Material

- Steel

- Coil Thickness

- 0.10 mm to 3.00 mm Millimeter (mm)

- Coil Weight

- As Per Customer Requirement Kilograms (kg)

- Width

- 3.20 mm to 1500 mm Millimeter (mm)

- Application

- Automobile Industry, Sheet Metal Manufacturers, Pipes & Tubes, Industrial & Engineering Parts, White Good Manufactures, etc.

GI Coils Roll Trade Information

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Packaging Details

- Pallet Packing, Plastic & Hessian Cloth and Export Quality Packing.

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Africa, Central America, Middle East, South America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2008

About GI Coils Roll

Galvanizing is a process of coating of layer of Zinc on steel material. Galvanizing process makes material corrosion resistant.Advantages

- Galvanized steel has lower cost then other material.

- Less maintenance.

Types

- Hot dip galvanized steel.

- Galvalume steel.

- Galvannealed steel.

- Electro galvanized steel.

Uses

- Build house. (Pillars)

- Washing machine, air conditioning, hair dryer.

- Car parts, buses & truck parts.

- Make ornaments, making doors, roofs.

Superior Galvanized Performance

Our GI Coils Roll feature an advanced galvanized coating that offers excellent protection against corrosion, making them especially suited for environments where durability is crucial. This robust surface treatment extends the lifespan of steel components and reduces the need for frequent maintenance, adding cost-effectiveness to their value.

Versatile Industrial Usages

These GI Coils find widespread use in the automobile industry, sheet metal manufacturing, production of pipes and tubes, as well as various industrial, engineering, and white goods applications. Their customizable specifications allow manufacturers to meet precise requirements for different manufacturing and fabrication processes.

FAQs of GI Coils Roll:

Q: How are GI Coils Roll typically used in the automobile industry?

A: In the automobile industry, GI Coils Roll are used to produce different components such as car bodies, chassis, and internal parts. Their corrosion-resistant galvanized finish enhances the longevity and safety of automotive components, ensuring vehicles remain durable even in harsh environments.Q: What are the advantages of using galvanized steel coils over regular steel?

A: Galvanized steel coils provide superior protection against rust and corrosion compared to regular steel. The zinc coating acts as a barrier, significantly extending the lifespan of products while minimizing maintenance costs and ensuring structural reliability in demanding applications.Q: When should a manufacturer choose GI Coils Roll over other materials?

A: Manufacturers should opt for GI Coils Roll when their products require enhanced corrosion resistance, durability, and a long service life, especially in industrial, automotive, or outdoor applications where exposure to moisture and chemicals is common.Q: Where are these GI Coils Roll supplied from, and who can order them?

A: These coils are exported, imported, and manufactured in India. Both domestic and international clients, including manufacturers in the automobile, engineering, and sheet metal sectors, can order coils tailored to their specific requirements.Q: What is the process involved in manufacturing GI Coils?

A: GI Coils are fabricated using high-quality steel, which is then treated with a galvanizing process where a protective zinc coating is applied. This involves cleaning, pickling, and immersing the steel in molten zinc to ensure uniform coverage and enhanced corrosion resistance.Q: How does customized coil weight and dimension benefit industrial users?

A: Customizable coil weight, width, and thickness allow industrial users to optimize material usage, reduce waste, and ensure seamless integration into existing production lines, promoting both efficiency and cost savings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Galvanized Steel Category

Galvanized Coil Sheets

Price 55 INR / Kilograms

Minimum Order Quantity : As per Customer Requirement Kilograms

Material : Steel

Usage : Automobile Industry, Sheet Metal Manufacturers, Pipes & Tubes, Industrial & Engineering Parts, White Good Manufactures, etc.

Application : Automobile Industry, Sheet Metal Manufacturers, Pipes & Tubes, Industrial & Engineering Parts, White Good Manufactures, etc.

Coil Thickness : 2.5mm Millimeter (mm)

Galvanized GPSP Steel

Price 65 INR / Kilograms

Minimum Order Quantity : As Per Customer Requirement Kilograms

Material : Steel

Usage : Automobile Industry, Sheet Metal Manufacturers, Pipes & Tubes, Industrial & Engineering Parts, White Good Manufactures, etc.

Application : Automobile Industry, Sheet Metal Manufacturers, Pipes & Tubes, Industrial & Engineering Parts, White Good Manufactures, etc.

Coil Thickness : 0.05mm to 4.00mm Millimeter (mm)

GP Higher Coating Steel Coils

Price 65 INR / Kilograms

Minimum Order Quantity : As Per Customer Requirement Kilograms

Material : Steel

Usage : Automobile Industry, Sheet Metal Manufacturers, Pipes & Tubes, Industrial & Engineering Parts, White Good Manufactures, etc.

Application : Automobile Industry, Sheet Metal Manufacturers, Pipes & Tubes, Industrial & Engineering Parts, White Good Manufactures, etc.

Coil Thickness : 0.15mm to 3.50mm Millimeter (mm)

GP Bright Coils

Price 55 INR / Kilograms

Minimum Order Quantity : As Per Customer Requirement Kilograms

Material : Steel

Usage : Automobile Industry, Sheet Metal Manufacturers, Pipes & Tubes, Industrial & Engineering Parts, White Good Manufactures, etc.

Application : Automobile Industry, Sheet Metal Manufacturers, Pipes & Tubes, Industrial & Engineering Parts, White Good Manufactures, etc.

Coil Thickness : 0.15mm to 3.50mm Millimeter (mm)

Send Inquiry

Send Inquiry